The assembly of SMD components (Surface Mount Device) in SMT technology (Surface Mount Technology) plays a fundamental role in modern electronics manufacturing. In the face of ongoing miniaturization of devices and growing expectations regarding their functionality, this technology has become the standard in the electronics industry.

➡️

What is SMT assembly?

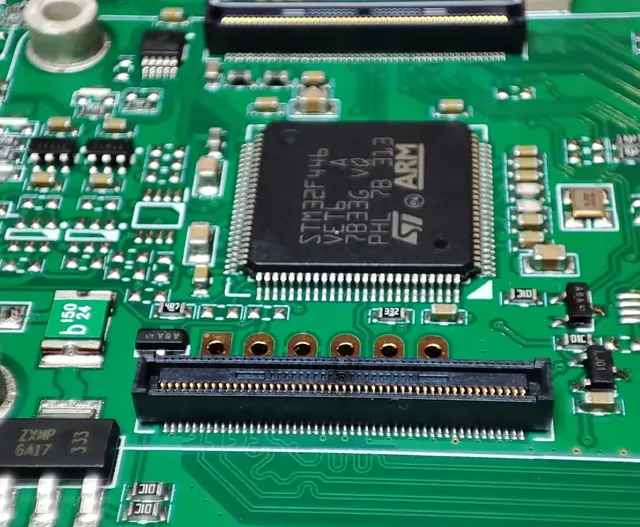

SMT assembly is a process in which electronic components are mounted directly on the surface of printed circuit boards (PCBs), in contrast to traditional through-hole assembly (THT – Through-Hole Technology). This method of SMD assembly opens up new possibilities in designing electronic devices, through the use of very small electronic components. As a result, it is possible to create more complex circuits that are also more functional and efficient.

SMT assembly is a process in which electronic components are mounted directly on the surface of printed circuit boards (PCBs), in contrast to traditional through-hole assembly (THT – Through-Hole Technology). This method of SMD assembly opens up new possibilities in designing electronic devices, through the use of very small electronic components. As a result, it is possible to create more complex circuits that are also more functional and efficient.

➡️

Advantages of SMD assembly

SMD assembly in SMT technology offers a number of advantages, including:

- Lower production costs – The smaller sizes of SMD components, which are associated with material savings, reduced space requirements on printed circuit boards (PCBs), and, most importantly, full automation of the production process, contribute to a significant reduction in production costs. Compared to THT assembly, the reduced material consumption and greatly improved efficiency of the production process significantly affect the competitive pricing of end products.

- High production efficiency – The automation of SMT assembly processes leads to a significant increase in production efficiency. Activities such as component placement using Pick&Place machines and soldering in a reflow oven are automated, allowing for the rapid execution of large production runs.

- Space-saving design – SMD components are significantly smaller than traditional THT components, which allows for the design of more compact devices. The ability to construct small-sized devices is invaluable in areas such as telecommunications, household appliances, and consumer electronics.

- Improved electrical performance – Shorter connections between elements in SMT assembly lead to reduced signal losses and better electrical efficiency, which is particularly important for advanced electronic devices, such as those used in medical, automotive, or military applications.

- Versatility in applications – SMT assembly is now widely used in the production of devices with diverse applications, such as audio systems, medical devices, and electronics for the automotive industry. The ability to integrate various components, such as sensors, Front-End signal processing modules, or integrated radio communication modules, gives developers significant freedom in design.

➡️

SMT assembly process

The SMT assembly process consists of several key steps that are essential for achieving a high-quality end product in electronics manufacturing:

1️⃣ Preparing the PCB for SMT assembly – The first step in the SMT assembly process is the proper preparation of the printed circuit board. The PCBs must be thoroughly cleaned to eliminate contaminants that could negatively impact soldering quality. After this step, solder paste is applied to the appropriate pads, typically using SMT stencil printing. The use of solder paste is crucial, as it bonds the SMD components to the PCB during the subsequent soldering process. Precise application of the paste ensures high-quality connections and minimizes the risk of cold solder joints.

2️⃣ Placing SMD components – During the component placement stage, advanced Pick&Place machines are utilized. These automatic devices place components with very high precision and speed on the previously prepared PCBs. The machines operate using complex algorithms that analyze the shape, dimensions, and correctness of the mounted components in real-time, as well as their proper placement and orientation on the PCBs, allowing for quick and effective production. Modern Pick&Place machines can achieve performance levels of tens of thousands of components per hour, greatly accelerating the overall production process.

3️⃣ SMD soldering process – Soldering is one of the critical steps in the SMT assembly process. This generally takes place in a reflow oven, where the boards are heated to the required temperature. This process causes the solder balls in the solder paste to melt, resulting in a permanent connection of the SMD components to the PCB. Accurately controlling the temperature and time using a suitable soldering profile, is essential to avoid damaging components or improper soldering. Modern reflow ovens are equipped with monitoring systems that ensure optimal conditions for every soldering stage.

4️⃣ Inspection and testing – Another step in the SMT assembly process involves testing each PCB, which is critical for ensuring production quality. Several parallel testing methods are typically employed. The first control consists of a visual inspection that allows for the detection of obvious defects. Simultaneously, automatic optical inspection (AOI) is utilized, using 3D technology in our case. This technology enables precise scanning of the PCB and identification of potential assembly errors, such as incorrect placement, incorrect orientation, missing or incorrectly marked components, as well as insufficient or excessive solder volume, inadequate wetting of the solder, solder bridges causing short circuits, or lack of solder joints.

For more complex SMD components, such as BGA (Ball Grid Array) devices, X-ray inspection is additionally employed. This method permits a thorough examination of solder connections that are not visible to the naked eye.

After the visual inspections, electrical and functional tests are performed to enable accurate verification of the tested circuit. Electrical tests cover checking relevant parameters such as voltage, current, and resistance, as well as analyzing signals in the circuits. Functional tests aim to verify the operation of the entire device according to its specifications. The wide range of testing methods guarantees that each product meets the required quality and functionality standards.

5️⃣ Final production steps – The final step in the SMT assembly process is the finalization of production. This includes separating the PCB panels into individual boards, conducting additional quality controls, packaging, and preparing for distribution. Final steps may involve final assembly, such as mounting in enclosures and adding emblems, labels, or performing laser marking on PCBs and enclosures, thereby enhancing the traceability of the final product.

➡️

Why is it beneficial to use professional SMT assembly services?

As a provider of SMT assembly services, we not only possess modern equipment but also the knowledge and experience necessary to carry out the assembly process effectively. Choosing professional SMT assembly services provides access to:

- High-quality services – We implement strict quality control procedures that significantly minimize the risk of production errors.

- Modern technologies – By continuously investing in the advancement of our production facilities, we maintain our services at the highest level, which translates into better quality and efficiency in production.

- Technical support – Utilizing the expertise of industry specialists allows clients to receive assistance and advice at every stage of the project, which is particularly useful for complex circuits and large orders.

In the case of SMT assembly at AssemTec Europe, clients also receive support in the form of a comprehensive offer for the supply of electronic components necessary for production, available at very attractive prices. We have proprietary tools that automate and speed up the pricing process while simultaneously checking the availability of components in our suppliers' warehouses. Our systems also suggest the possibility of using suitable substitutes and compare prices from multiple suppliers, allowing the selection of the most cost-effective option.

➡️

SMD assembly at AssemTec Europe

SMD assembly in SMT technology is a key process in electronics manufacturing, offering many benefits such as high production efficiency and excellent electrical performance. Thanks to SMT technology, it is possible to create advanced devices in smaller sizes. Utilizing the professional SMT assembly services offered by AssemTec Europe is a step toward ensuring the highest quality and efficiency in production. SMT assembly is a technology that shapes the face of modern electronics, providing manufacturers with the opportunity for innovative approaches to design and manufacture complex electronic devices. With the technical support provided by AssemTec Europe, clients gain the ability to optimize their projects, adapt them for serial production, and equip assembled devices with components offered at very competitive prices.